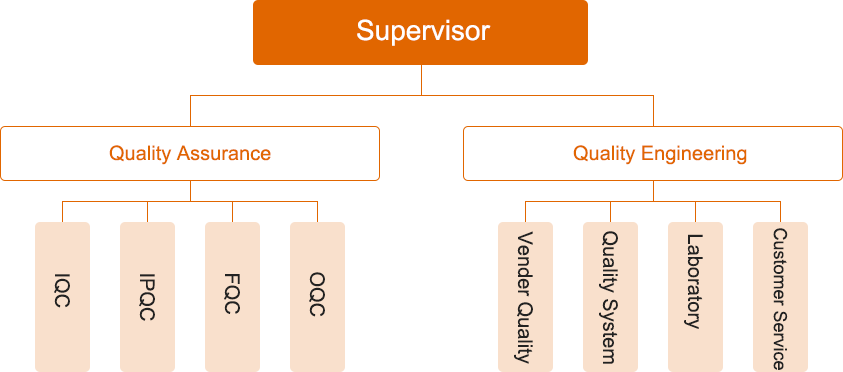

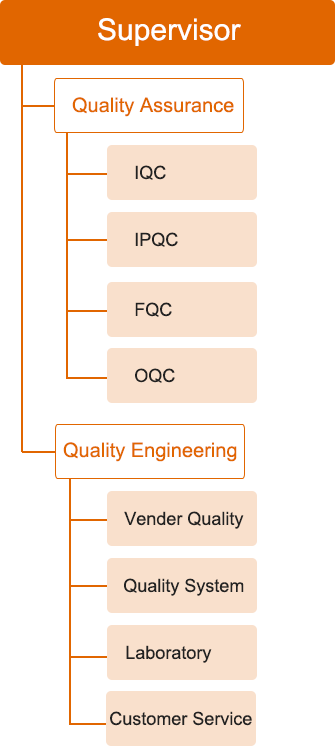

Quality Assurance

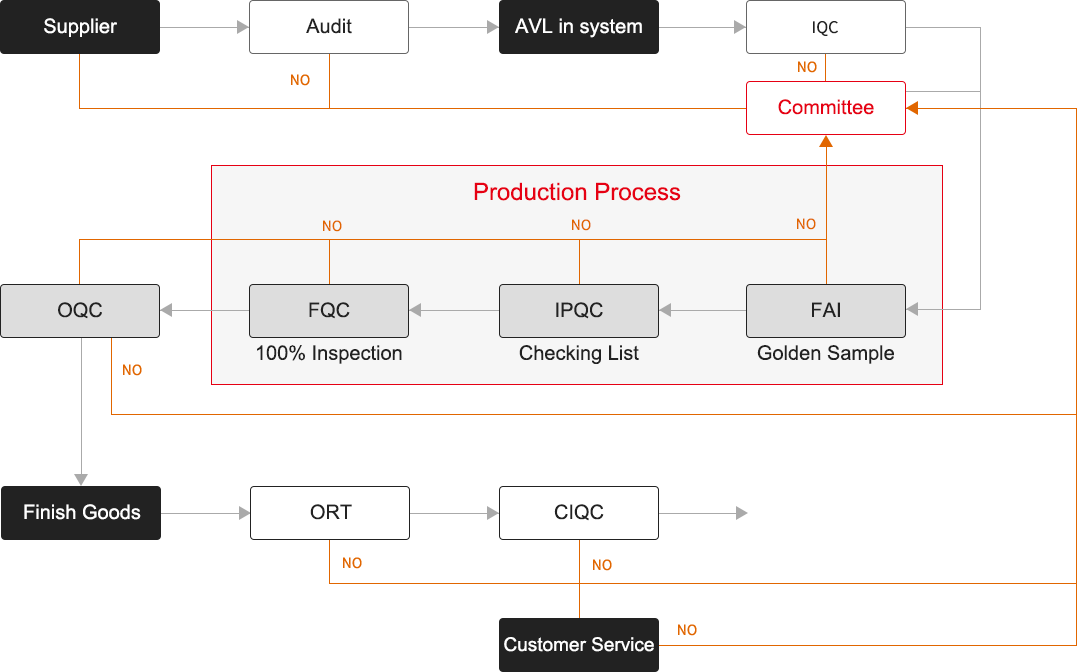

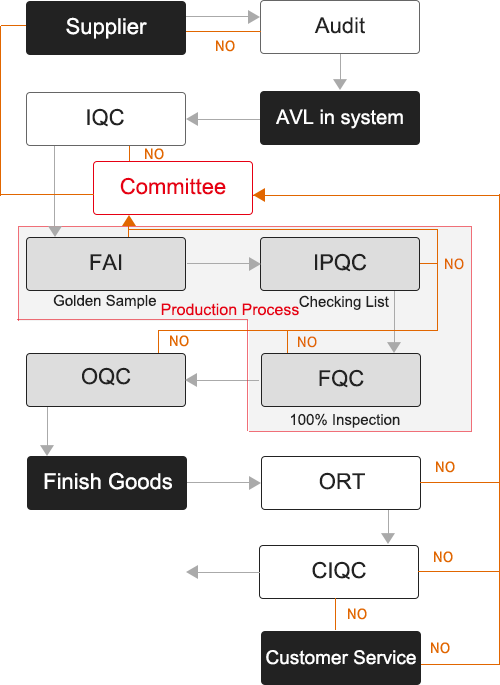

Quality Control Process

Test Equipment

CMS

IPX7 Sink

3D Projector

Salt spray tester

X-ray

Pulsed Coil Tester

Wire Insertion Force Test Instrument

Charged Coating Abrasion Test Instrument

Charged Coating Abrasion Test Instrument

Gas chromatograph

Vibration Test Instrument

Drop Test Instrument

Constant Temperature and Humidity Instrument

Constant temperature and humidity meter

Pin Hole Test AC Power Supply

Experiment Capability

Test Item

Testing condition

Life Test

Pink noise, White noise, IEC 268-5 2.83V 96H

Heat Test

+ 60℃±2℃ 48 hours

Cold Test

- 25℃±3℃ 48 hours

Humidity Test

+ 40℃±2, Relative Humidity 90 - 95%, 48 hours

Temperature/ Humidity in Operating

60℃ 30 minutes, Within 10 minutes , -40℃ 30 minutes, 5 times, In total 5.8H

Salt Spray Test

Salt spray test for 24H, Fellow IEC - 68 - 11 - ka Standards

Drop Test

The speaker shall be dropped (A) times on iron as shown in the figure (A=6)

Packed Vibration Test

Amplitude 1.5mm, Sine sweeping 3H with 30±15HZ, along X, Y, and Z axes

ISTA Packaging drop Test

Drop one corner, three edges and six surfaces, Test height is 1m, Drop 6 times

End product drop Test

Test height is 1m, Drop 6 times

HSF compliance Test

HSF compliance test with material, WIP, finished product and accessories.

RCA charged coating abrasion Test

Applying 175g pressure with RCA tape back and forth 200 times.(According to customer standards)

Wire insertion force Test

Plug the wire plug with the block for 100 times; insertion force and pull force according to the "wire plug force standard”.

Wire tension Test

The wire core is fixed on the pull meter and the other end is fixed with wire Housing.

Thermal shock Test

Begin with 25℃ and humidity 60%, Temperature & humidity requirements change with time according to “TH test profile”. In total 53H

Electroplated layer abrasion Test

With three layers of clean cloth wrapped in the upper part of the 500g weight, dip in the purity of 99% alcohol, then scrub the Plating surface 100times, Each trip 25mm.

Pinhole test

According to JIS C-3003-6. Inspection of copper wire.

water-proof test

IPX7

RoHS2.0 O-benzene test

Eu added four hazardous substance tests for DEHP/DBP/BBP/DIBP o-benzene on July 21st, 2019.

Quality System

- Define

- Measurement

- Analysis

- Improvement

- Control

Core

- Data collection

- Pareto

- Histogram

- Cause-Effect diagram

- Control chart

- Stratification

- Scatter

Skill

- DOE

- Reliability

- CPK

- GR & R

- PFMEA

- QC flow Chart

Engineering Experiment

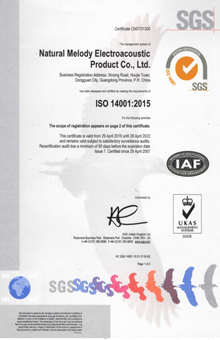

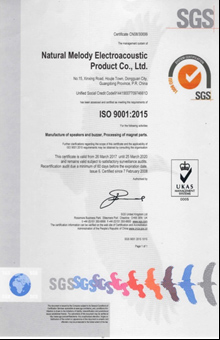

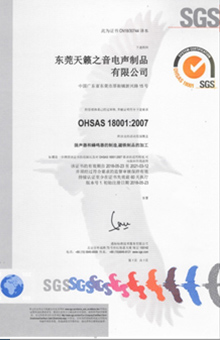

Certifications

ISO 14001 certificate

ISO 9001 certificate

QC080000 certificate

OHSAS 18001 certificate